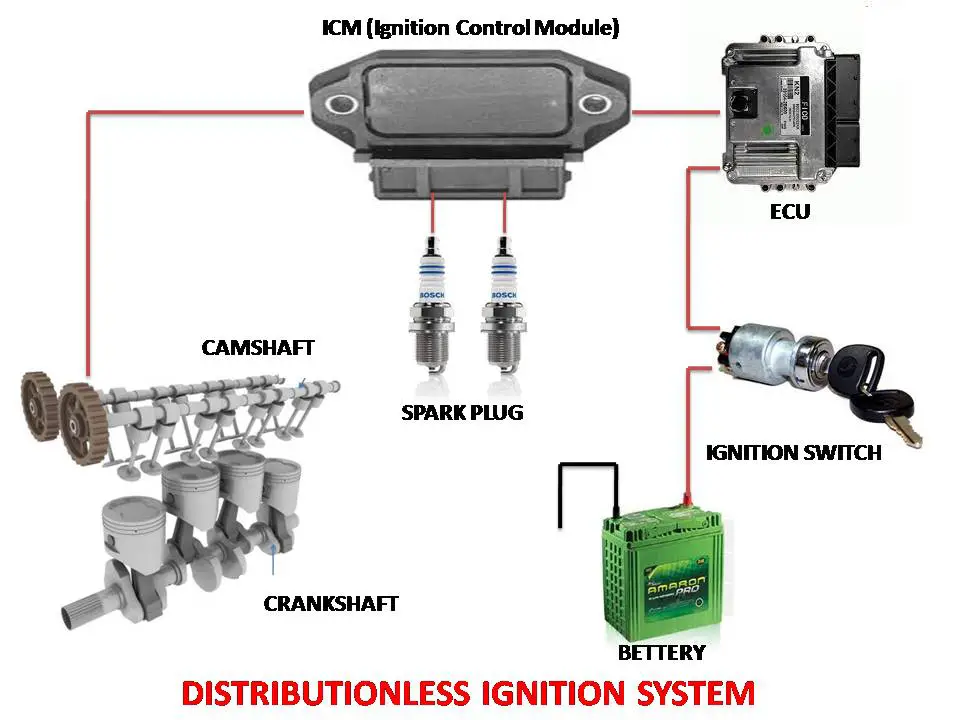

Ignition system is used to produce a spark in the engine cylinder towards the end of the compression stroke. Ignition systems are of different types. Distributorless ignition system is a modern type ignition system which do not use a mechanical distributor.

Distributorless Ignition System:

Construction:

In Distributorless ignition system , instead of using mechanical distributor , various electronics components are used. They are described below.

- Battery :- Battery is used as a powerhouse for the ignition system.

- Ignition switch :-Ignition switch is a switch to turn on or off the ignition system.

- E.C.U :- Electronic control unit is a mini computer, which coordinate all other components by receiving signals from various sensors and gives proper signals to ignition control unit.

- I.C.U :- ICU is an electronic control sub unit contains multiple ignition coils in it. It receives signals from camshaft position sensor, Crankshaft position sensor and ecu. According to this data ignition coils produce high voltage individually for each spark plug.

- Magnetic triggering device :- This is a device which consists of a toothed wheel along with a sensor. All the teeth are equally spaced except one. There are two types triggering wheels are there. One is used to know the exact position of crankshaft and the other is used to know the position of camshaft.

- Spark plug :- Spark plug is used to generate spark, generally one per cylinder.

Working:

When we switch on the ignition switch, the current from battery starts to flow through ignition switch to ECU of the vehicle. ECU process various data from sensors and calculate the ignition timing continuously.

At the same time the triggering wheel mounted on camshaft and crankshaft have equally spaced teeth except one which identify the position of crankshaft and camshaft. The position sensors are equipped with a magnetic coil which generate magnetic field continuously. When the gap of triggering wheel came in front of the position sensor, a fluctuation of signal would occur. These signals then sent to ICU. ICU senses the signal and stops the flow of current to the primary winding of the coil.

When the gap go away from the sensor the corresponding signal again sent to ICU and ICU allows the current to flow to the primary winding of the coil.

This continuous process create a magnetic field in the primary coil which causes an emf to induce in secondary windings of the coil. This voltage may increase up to 70,000 volts. This high voltage is then sent to spark plug which make quality spark with precise timing.

Application:

- Almost all new generation cars with VR6, V6 engines using this system.

- First used in volkswagen passat’s 2.8L VR6 engine.

- Some super sport bikes are also using DIS.

Advantages:

- No distributor cap and rotor.

- Less engine drag

- No timing adjustment.

- Precise spark timing.

- No moving parts to worn out.

Disadvantages:

- If one of the sensor failed the whole system will shutdown.

- As there is more number of coils, initial cost become high.

- High maintenance cost.